Polyvinyl acetal flat enameled copper wire is a specially designed electromagnetic wire that combines the insulation properties of acetal resin and the structural advantages of flat conductors. It has unique application value in power equipment.

Insulation material composition: Polyvinyl acetal resin (such as formal PVF or butyral PVB) is used as the insulating coating, which has high dielectric strength (above 45kV/mm) and excellent oil resistance, and is particularly suitable for environments such as oil-immersed transformers.

The ether bonds and hydroxyl groups in the resin molecular chain give the paint film strong adhesion (0-2 levels in the 100-grid test) and wear resistance, which is suitable for high-speed winding processes.

Flat conductor design: The rectangular cross-section significantly increases the slot fill rate to more than 85%, reduces the winding gap, and enhances the heat dissipation efficiency; the multi-strand twisted structure can reduce the skin effect and increase the motor efficiency by 3%-5%.

Compared with round wire, flat wire is more suitable for making transposed conductors for large transformers, effectively reducing eddy current losses.

Temperature resistance and environmental adaptability: The temperature resistance grade is E (105-120℃), the long-term working temperature is -40℃ to 120℃, and the heat shock resistance passes the 150℃/168h test.

It has outstanding oil resistance and high temperature hydrolysis resistance, but poor moisture resistance, and needs to avoid humid or chemical corrosion environments.

Mechanical and electrical properties: The tensile strength of the paint film is above 300MPa and can withstand repeated bending (1d-3d radius winding test).

In the drive motor of new energy vehicles, the pressure resistance of the paint film structure with 6 layers or more reaches 2000V, meeting the IP67 protection requirements.

Application areas

1. Power transformers

The flat wire structure is used in the transposed conductor to reduce eddy current loss and improve the energy efficiency of large transformers.

The oil-immersed transformer relies on its oil resistance and hydrolysis resistance, and has significant long-term stability.

2. Motor windings

In AC/DC motors and servo motors, flat wire design improves power density (e.g., a permanent magnet motor reaches 4.5kW/kg).

The multi-strand twisted structure in traction motors reduces high-frequency losses.

Flat enameled copper wire specifications:

| Name | Flat enameled copper wire |

| Conductor | Copper |

| Dimension | Thickness:0.3 mm -10mmWidth:1.0mm -22mm |

| Thermal Class | 130(Class B),155(Class F),180(Class H),200(Class C).220(Class C) |

| Insulation Thickness: | single /heavy |

| Standard | IEC 60317/60851 GB/T 6109/7095 NEMA MW 1000 |

| Certificate | UL |

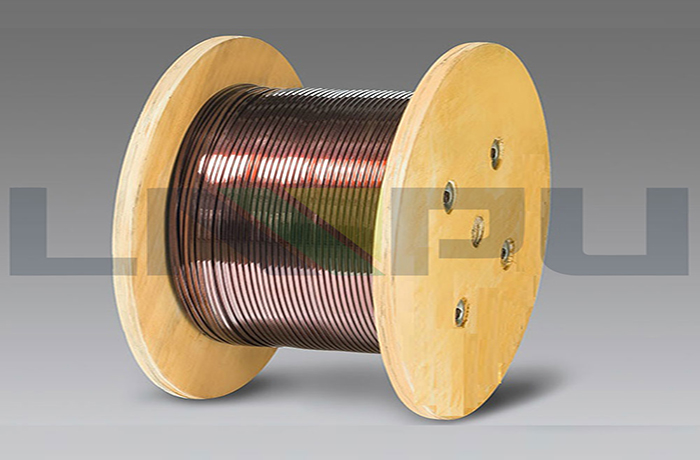

| Packing | 30kg-150kg ply-wood spool(250*400 / 250*500/ 250*600/ 250*730) |