Introduction of enamelled Copper wire:

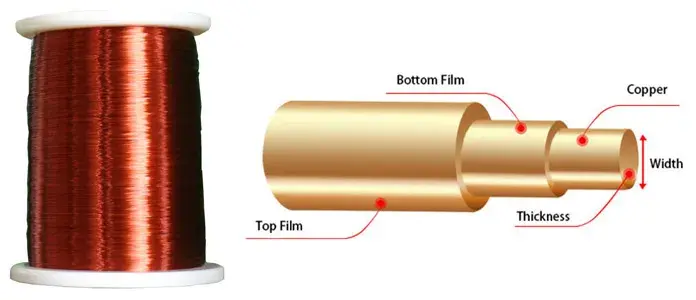

Enameled copper wire is made of copper rod, which are draw by the specification mould,it is the baked winding wire with multiple-layers of insulating paint after annealing softening treatment.

Zhengzhou LP Industry enameled copper wire is based on the national standard GB, the US NEMA standard and the EU IEC60317 standard or the technical requirements of customers to formulate production standards. The main performance control indicators are conductor size, conductor fillet size, insulation thickness, overall size, elongation, Spring back, flexibility and adhesion, room temperature (high temperature) breakdown voltage, thermal shock and other items.

Enamelled round copper wire guage

| AWG | Bare Diameter(mm) | AWG | Bare Diameter(mm) | SWG | Bare Diameter(mm) | SWG | Bare Diameter(mm) |

| 1 | 7.35 | 26 | 0.40 | 1 | 7.62 | 26 | 0.46 |

| 2 | 6.55 | 27 | 0.36 | 2 | 7.01 | 27 | 0.42 |

| 3 | 5.82 | 28 | 0.32 | 3 | 6.40 | 28 | 0.38 |

| 4 | 5.18 | 29 | 0.29 | 4 | 5.89 | 29 | 0.35 |

| 5 | 4.62 | 30 | 0.25 | 5 | 5.38 | 30 | 0.31 |

| 6 | 4.12 | 31 | 0.23 | 6 | 4.88 | 31 | 0.29 |

| 7 | 3.67 | 32 | 0.20 | 7 | 4.47 | 32 | 0.27 |

| 8 | 3.26 | 33 | 0.18 | 8 | 4.06 | 33 | 0.25 |

| 9 | 2.91 | 34 | 0.16 | 9 | 3.66 | 34 | 0.23 |

| 10 | 2.59 | 35 | 0.14 | 10 | 3.25 | 35 | 0.21 |

| 11 | 2.30 | 36 | 0.13 | 11 | 2.95 | 36 | 0.19 |

| 12 | 2.05 | 37 | 0.11 | 12 | 2.64 | 37 | 0.17 |

| 13 | 1.83 | 38 | 0.10 | 13 | 2.34 | 38 | 0.15 |

| 14 | 1.63 | 39 | 0.089 | 14 | 2.03 | 39 | 0.13 |

| 15 | 1.45 | 40 | 0.079 | 15 | 1.83 | 40 | 0.12 |

| 16 | 1.29 | 41 | 0.071 | 16 | 1.63 | 41 | 0.11 |

| 17 | 1.15 | 42 | 0.064 | 17 | 1.42 | 42 | 0.10 |

| 18 | 1.02 | 43 | 0.056 | 18 | 1.22 | 43 | 0.091 |

| 19 | 0.91 | 44 | 0.051 | 19 | 1.02 | 44 | 0.081 |

| 20 | 0.81 | 45 | 0.045 | 20 | 0.91 | 45 | 0.071 |

| 21 | 0.72 | 46 | 0.040 | 21 | 0.81 | 46 | 0.061 |

| 22 | 0.64 | 47 | 0.035 | 22 | 0.71 | 47 | 0.051 |

| 23 | 0.57 | 48 | 0.032 | 23 | 0.61 | 48 | 0.041 |

| 24 | 0.51 | 49 | 0.028 | 24 | 0.56 | 49 | 0.030 |

| 25 | 0.45 | 50 | 0.025 | 25 | 0.51 | 50 | 0.025 |

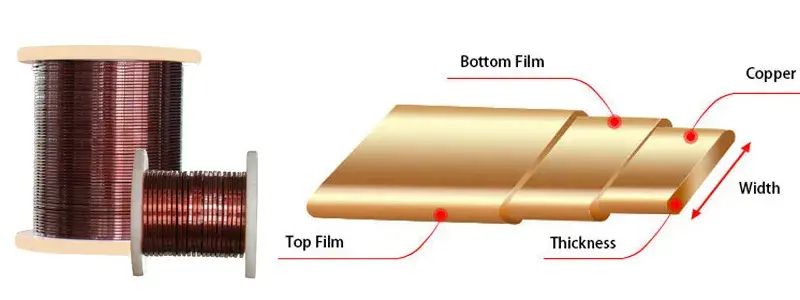

Enamelled Flat Copper wire guage

| Name | Enameled Rectangular Copper Wire |

| Conductor | Copper |

| Dimension | Thickness(a):0.3-10.0mm; Width(b):1-22mm |

| Special Dimension | 2.5*25mm,4*25mm |

Enamelled Square Copper wire guage

| Name | Enameled Square Copper Wire |

| Conductor | Copper |

| Dimension | Thickness(a)/Width(b):0.45-6mm |

| Special Dimension | send the requirement’s size, custom the size of copper wire |

Thermal Class and coating materials of Enamelled copper wire:120(Class E), 180(Class H), 200(Class C), 220(Class C+), 240(Class HC)

| Thermal Class | Insulation Type |

| 105℃ | Formvar |

| Polyurethane Bondable Formvar Bondable Polyurethane Nylon Bondable | |

| 130℃ | Polyurethane Nylon |

| 155℃ | Polyurethane 155 |

| Polyurethane Nylon 155 | |

| Polyurethane 155 Bondable Polyurethane Nylon 155 Bondable | |

| 180℃ | Polyurethane 180 |

| Polyester-imide | |

| Polyurethane Nylon 180 | |

| Polyurethane Bondable Polyester-amide-imide Bondable Solderable Polyester Bondable | |

| Polyurethane Nylon | |

| Solderable Polyester | |

| Solderable Polyester Nylon | |

| Polyurethane 180 Bondable Polyurethane Nylon 180 Bondable | |

| 200℃ | Polyester 200 |

| Polyester A / I Topcoat | |

| Polyester A / I Polyamideimide | |

| Polytetrafluoloethylene (Teflon) | |

| 240℃ | Polyimide – ML |

Coating of Enamelled copper magnet wire: single coating or grade 1, double coated or grade 2

Zhengzhou LP Industry enameled copper magnet wire’s characteristic:

Advantage: Electrical conductivity, excellent thermal stability, scratch resistance, solvent resistance, with good heat dissipation and high field efficiency after wingding performance and the advantages of high efficiency magnetic field.

Executive standards: IEC, JIS, GB and NEMA

Normal package: Spool size PT4, PT10, PT15, PT25 , ply-wood spool( 250*400/250*500*250*600/250*730mm)