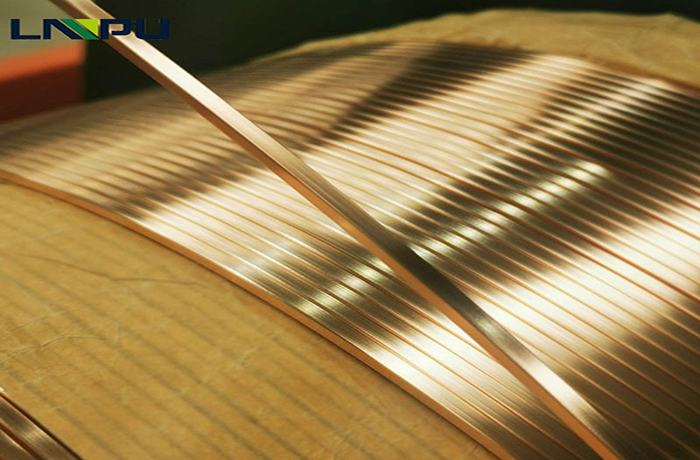

What is enameled square copper wire?

Enameled square copper wire is a square cross-section winding wire with high-purity copper conductor and special insulating varnish coating on the surface. Compared with traditional round wire, its unique square structure can achieve higher space utilization (fill factor increased by 15%-20%), and is widely used in high-frequency transformers, motors, inductors and other precision electromagnetic components, helping to upgrade energy efficiency and miniaturize equipment.

Performance advantages:

High conductivity: 99.99% oxygen-free copper (OFC) is selected, with a resistivity of ≤0.01724 Ω·mm²/m, and the conductivity efficiency is better than the industry standard.

Tight stacking design: The square cross-section reduces the gap between wires, saving 10%-15% space compared to round wires at the same cross-sectional area, and improving the winding density.

Excellent insulation performance: Multi-layer polyesterimide (PEI), polyamideimide (AI) or corona-resistant paint layer is optional, with a temperature resistance of 180℃~220℃ and a breakdown voltage of ≥8kV/mm.

Mechanical strength optimization: Special annealing process ensures the flexibility of copper materials, strong paint film adhesion, anti-bending and scratch resistance, suitable for automatic winding equipment.

Structural design advantages: The flat cross-section improves the compactness of the winding and reduces eddy current losses, especially suitable for space-constrained scenarios such as motor stators and transformers.

Application scenarios:

New energy field: electric vehicle drive motor, charging pile high-frequency transformer

Industrial equipment: servo motor, inverter inductor, UPS power supply

Consumer electronics: mobile phone wireless charging coil, Mini LED backlight module

Aerospace: high power density motor winding

Product Parameters:

| Conductor | Square Copper Wire |

| Dimension | Copper:Thickness(width)/a(b) 0.45-6.0mm |

| Thermal Class(℃) | 180(Class H);200(Class C);220(Class C +); 240(Class HC) |

| Insulation thickness | Single, Heavy |

| Certificate | UL |

| Standard | IEC, NEMA, GB, JIS |

| Packing | 30kg-150kg ply-wood spool(250*400/250*500/250*600/250*730) |

| Application | Transformer;generator;refrigeration System Class C generators UPS power supply,electronic transformer etc. |