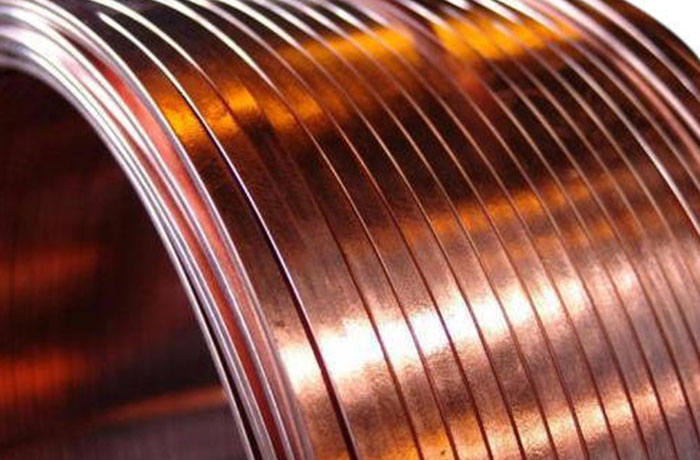

Enamelled flat copper wire is a type of magnet wire with a flat cross-section and an insulating enamel coating on its surface. It is widely used in electrical applications that demand tight winding, high current-carrying capacity, and good heat dissipation.

Enameled Flat Copper Wire Features

High-quality conductor material: High-purity oxygen-free copper rods are used, which are processed into rectangular cross-section conductors through multiple drawing passes, four-roll rolling, and precision annealing processes, featuring low resistance characteristics under high current density.

Insulation performance: It has excellent insulating properties; the insulation layer is resistant to peeling and can effectively prevent short circuits.

High slot fill factor: The rectangular cross-section design increases the motor slot fill rate by 30%-40%. Under the same volume, it can increase the conductor cross-sectional area, reduce winding resistance, and improve motor efficiency by 2%-5%.

Mechanical properties: high mechanical strength, good adhesion, scratch resistance, suitable for winding complex coils.

Applications:

New energy vehicle: Motors made with enamelled flat copper wire have advantages such as high slot fill factor, excellent heat dissipation, and low loss, making them well-suited for powering new energy vehicles.

Industrial high-efficiency motors: Motors manufactured with enamelled flat copper wire are highly efficient and low in noise.

Servo motors: Flat copper wire windings have a compact structure and reduce inductance by 30%, enabling rapid current changes.

Enameled Flat Copper Wire Specifications

| Name | Enameled Flat Copper Wire |

| Conductor | Copper |

| Dimension | Thickness(a)0.3一10.0mmWidth(b):1.0一22mm |

| Thermal Class | 120(Class E), 180(Class H), 200(Class C), 220(Class C+), 240(Class HC) |

| Insulation Thickness | G1, G2 or single build, heavy build |

| Standard | IEC60317-16,60317-16/28,MW36 60317-29BS6811,MW1860317-18 ,MW20 60317-47 |

| Certificate | UL |

| Packing | 30kg-150kg ply-wood spool(250*400 / 250*500/ 250*600/ 250*730) |

| Standard | IEC,NEMA,GB,JIS |