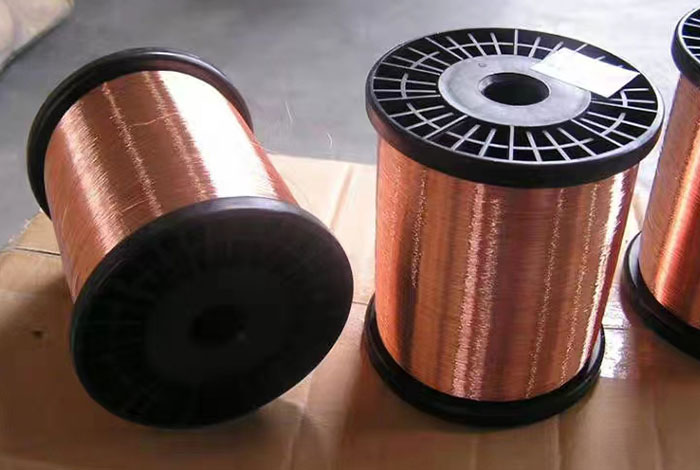

Enameled round copper wire is a type of magnet wire, featuring a round copper core with an outer insulating enamel coating. This structure endows it with excellent wire winding flexibility and a high slot fill factor, meeting the needs of various electrical applications.

Enameled Round Copper Wire Features

High-quality conductor material: High-purity oxygen-free copper rods are used and processed into circular cross-section conductors through multiple drawing passes and precision annealing processes, featuring low resistance characteristics under high current density.

Insulation performance: It has excellent insulating properties; the insulation layer is resistant to peeling and can effectively prevent short circuits.

Excellent flexibility: It can withstand 180° bending for 3 times without paint film cracking. The elongation of 0.050 mm conductor is ≥14%, and that of 0.320 mm conductor is ≥29%. The rebound angle is ≤30°, ensuring tight fit with the slot during winding and improving the slot fill rate.

Corrosion resistance: The enameled round copper wire has a stable coating material with tight wrapping, so it can be used for a long time in humid, oily, and even mildly acidic or alkaline environments without being easily corroded

Applications:

motors: Enameled round copper wire has good flexibility, and its circular cross-section allows for tight arrangement. This enables more turns to be wound within the limited motor housing, thereby improving the motor’s power density.

Transformers: Enameled round copper wire has low conductive loss, and its insulation layer is voltage-resistant, making it suitable for transformers.

Various electronic components, such as inductance coils and relays: These components require wires to have a small diameter, a thin insulation layer, and the ability to work at high frequencies, making enameled round copper wire highly suitable.

| Name | Enameled Round Copper Wire |

| Conductor | Copper |

| Dimension | 0.016一7.0mm |

| Thermal Class | 120(ClassE),180(ClassH),200(ClassC), 220(ClassC+), 240(Class HC) |

| Insulation Thickness | G1, G2 |

| Standard | IEC,NEMA,GB,JIS |

| Certificate | UL |

| Packing | PT-4-PT-200 or ply-wood-spool |